Usoro mmepụta na usoro nke ọkụ na-ekpo ọkụ na-ekpo ọkụ ribbed ígwè mmanya

Usoro ndabere:

N'ahịa rebar dị ugbu a, hrb400e na-enweta ihe ndị ọzọ.Usoro ike microalloy bụ ụzọ isi mepụta hrb400e n'ụwa.Microalloy bụ tumadi vanadium alloy ma ọ bụ niobium alloy, nke na-eri ọtụtụ ihe alloy kwa afọ.N'ihi oke ịnweta ịnweta nwere vanadium na niobium, ọkọnọ nke ihe ndị a na-ekekọta ihe na-esikwa ike.Ya mere, ọ bụrụ na ihe alloy nke hrb400e ígwè mmanya nwere ike ibelata, ọ ga-emepụta nnukwu uru akụ na ụba na nke ọha mmadụ.

N'ime teknụzụ dị ugbu a, ahịrị nrụpụta waya abụọ na-agbagharị na-enweghị ibelata na nha igwe igwe na-agbagharị agbagharị na-anabatakarị vanadium alloy ike iji mepụta hrb400e, yana ọnụọgụ pasentị vanadium bụ 0.035% ruo 0.045%.

Patent China cn104357741a na-ekpughe ụdị hrb400e ike dị elu nke ala ọma jijiji na-eguzogide ígwè na usoro mmepụta ya.Site na usoro ahụ, a na-emepụta ngwaahịa a rụchara site na mbelata na nha igwe igwe na-akpụ akpụ, nke nwere ike hụ na a na-atụgharị nchara nchara na obere okpomọkụ nke 730 ~ 760 ℃ iji nweta N'ihi na ọka dị mma, usoro a adịghị mma maka ahịrị mmepụta. na-enweghị ibelata nha igwe igwe.Chinese patent cn110184516a kpughere a nkwadebe usoro nke elu waya φ6mm ~ hrb400e coiled ịghasa.Site n'enyemaka nke ike na-agbagharị ngwa ngwa nke ngwá ọrụ, obere okpomọkụ na-atụgharị na-amalite site na okpomọkụ okpomọkụ, na mmepụta na-enweghị microalloying na-emezu.Mwepu nke usoro a bụ na ihe ndị a chọrọ maka ike na moto ịrụ ọrụ nke ngwa ike na-agbagharị agbagharị dị oke elu, karịsịa maka ahịrị mmepụta nke torsion rolling, nke na-ebelata ndụ nnwale nke akụrụngwa ma na-abawanye ụgwọ mmezi nke akụrụngwa, na ike mkpụrụ nke elu waya φ6mm ~ hrb400e eriri igwe na-emepụta site na usoro a bụ njupụta.Ọnụego ezughi oke, ọ siri ike ikwenye ọnụego ntozu arụmọrụ.

Ihe mmejuputa nka nka:

Ihe ohuru ohuru a bu n’obi inye usoro maka imepụta ogwe nchara na-ekpo ọkụ na-ekpo ọkụ, ọkachasị usoro maka imepụta ejula akpọnwụ akpọnwụ maka waya dị elu φ8 ~ φ10mm ~ hrb400e, nke na-emeri adịghị ike ndị a kpọtụrụ aha n'elu nke nka mbụ wee belata mmepụta. akwụ ụgwọ.

Atụmatụ nka nka nke ihe mepụtara ugbu a:

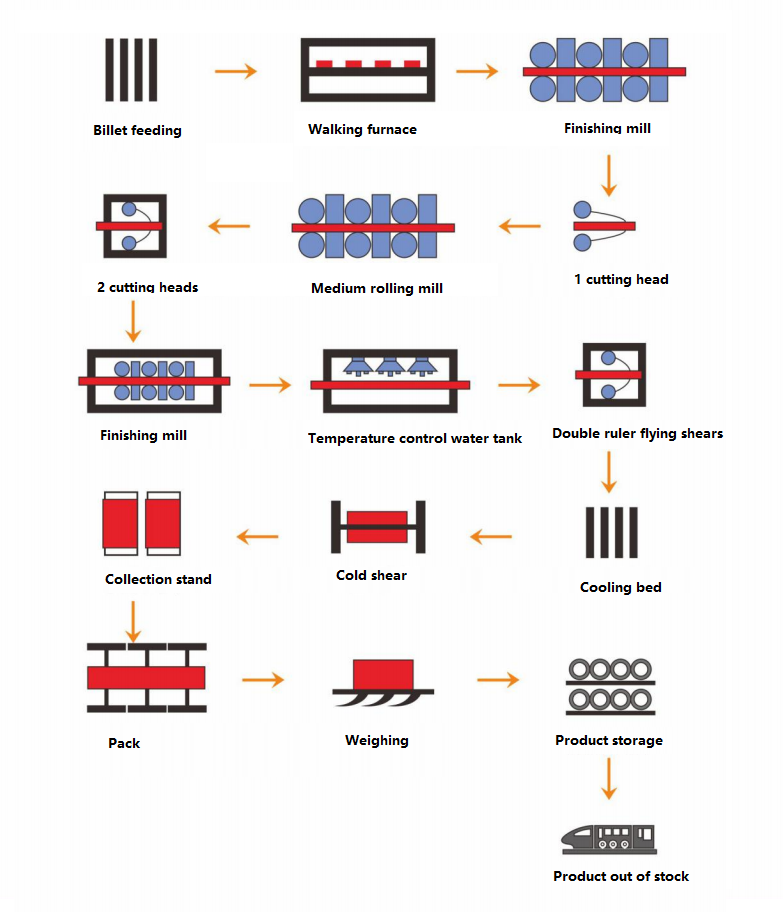

Usoro mmepụta nke igwe na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ, nkọwa nke eriri waya ribbed bụ φ8 ~ φ10mm, na usoro nkà na ụzụ na-agụnye ikpo ọkụ - billeting - rough rolling - medium rolling - cooling - pre-finshing - cooling - finishing - cooling na-agbagharị - Tebụl igwe na-eme ka ikuku dị jụụ-nchịkọta eriri igwe-iji nwayọ nwayọ;pasent nke ihe mejupụtara kemịkalụ nke ígwè bụ c = 0.20% ~ 0.25%, si = 0.40% ~ 0.50%, mn=1.40% ~ 1.60%, p≤0.045%, s ≤0.045%, v=0.015% ~0.020%, ndị ọzọ bụ Fe na ihe ndị na-adịghị ọcha na-apụghị izere ezere;isi usoro nzọụkwụ na-agụnye: ọkụ okpomọkụ bụ 1070 ~ 1130 ℃, na prefinishing Rolling okpomọkụ bụ 970 ~ 1000 ℃, na finishing Rolling okpomọkụ bụ 840 ~ 1000 ℃.880 ℃;Ịtọ okpomọkụ 845 ~ 875 ℃;okpomọkụ ikpeazụ na-atụgharị dị n'okpuru okpomọkụ recrystallization nke mpaghara austenite;ngwa ngwa jụrụ oyi site na fan na tebụl rola ikuku jụrụ oyi, olu ikuku bụ 100%;The okpomọkụ nke mkpuchi bụ 640 ~ 660 ℃, okpomọkụ nke okpomọkụ nchekwa cover bụ 600 ~ 620 ℃, na oge na okpomọkụ ichebe cover bụ 45 ~ 55s.

Ụkpụrụ nke mmepụta ihe: na okpomọkụ nke 840-880 ℃, a na-agbatị ọka austenite site na nrụrụ na-atụgharị, ma recrystallization anaghị eme.Otú ọ dị, a na-emepụta eriri deformation na mkpụrụ ọka austenite, na njedebe nke eriri deformation na-adịkarị n'ókè nke ọka, na e nwekwara ihe ndọghachi azụ na ọka dị ka ihe àmà na-egosi oke ọka iji kewaa ọka elongated austenite.N'oge mgbanwe site na austenite ka ọ bụrụ ferrite, ma oke ọka austenite elongated na mpaghara nrụrụ nke mkpụrụ osisi na-arụ ọrụ dị ka saịtị nucleation maka ferrite, na-ebute nchacha nke ferrite mgbe mgbanwe gasịrị.Obere okpomọkụ na-atụgharị n'ime igwe ihe na-emecha na-ebelata ibu na-akpụ akpụ nke igwe ihe na-agbagharị agbagharị na nke etiti na igwe ihe eji emecha ma na-abawanye ndụ ọrụ nke akụrụngwa.

Mmetụta bara uru nke ihe a na-emepụta bụ ndị a: site n'ịgbakwunye obere v maka ike microalloy, ike mkpụrụ na-eme ka ọ dịkwuo mma, v na c na-emepụta carbides, nke a na-ebuli n'oge usoro jụrụ oyi mgbe ọ na-atụgharị, ma na-arụ ọrụ nke mmiri ozuzo na-ewusi ike. .Mkpanaka waya na-ekpo ọkụ na-ekpo ọkụ nke ihe a na-emepụta nwere ike nkwụsị nke 600-700mpa, ike nke 420-500mpa, nkezi mkpụrụ ike nke ihe dị ka 450mpa, na agt>10%, nke na-eme ka njedebe zuru oke.Ike mkpụrụ ahụ kwụsiri ike, yana ọnụego ntozu arụmọrụ karịrị 99%.Ihe mepụtara na teknụzụ na-edozi nsogbu ahụ bụ na igwe igwe na-agbagharị agbagharị siri ike ịrụgharị obere okpomọkụ, na-ebelata ọnụ ahịa n'ihu n'ihu na ike mmepụta adịghị ebelata, ma na-eweta uru akụ na ụba dị elu.

Ụzọ zuru ezu

A kọwakwuru ọdịnaya nke ihe a na-emepụta ugbu a n'okpuru ebe a na-ejikọta ya na ihe ngosi.

The mmepụta usoro nke otu elu waya φ8mm ~ φ10mmhrb400e chikọtara ejula.Usoro ntụgharị bụ: okpomọkụ na-apụ apụ: 1080 ~ 1120 ℃, na-abanye tupu ịmechaa mpịakọta 1030 ~ 1060 ℃, na-abanye n'ime imecha okpomọkụ: 850 ~ 870 ℃, okpomọkụ na-atụgharị: 850 ~ 870 ℃, ikuku ikuku olu 100%, ntinye mkpuchi okpomọkụ 640 ~ 660 ℃, 600 ~ 620 ℃ nke okpomọkụ ichebe cover, oge na okpomọkụ ichebe cover bụ 45 ~ 55s, na ọ cools ndammana.Ihe mejupụtara kemịkalụ nke eriri waya nke ụdị ihe a na-emepụta ugbu a ka egosiri na Tebụl 1, na ihe eji arụ ọrụ nke eriri waya nke ihe nrụnye nke ihe a na-emepụta ugbu a gosipụtara na tebụl 2.

Ngwakọta kemịkalụ (wt%) nke mkpanaka waya nke ihe atụ tebụl

Isiokwu 2 Mechanical Njirimara nke ihe atụ waya mkpanaka

The mkpụrụ ike nke elu waya φ8mm ~ φ10mmhrb400e coiled ejula na-emepụta site na usoro nke mepụtara bụ na nso nke 420 ~ 500mpa, na agt bụ n'elu 10%, ike mkpụrụ ruru bụ n'elu 1.35, na metallographic Ọdịdị bụ tumadi ferrite. na pearlite.arụ ọrụ kwụsiri ike, ike mkpụrụ zuru oke na oke agt, ihe ịga nke ọma nke usoro a dị oke mkpa iji belata ọnụ ahịa mmepụta yana ịba ụba uru maka ahịrị mmepụta nke torsion torsion nke nwere akụrụngwa ochie.

Atụmatụ nka na ụzụ:

1. Usoro mmepụta nke na-ekpo ọkụ na-ekpo ọkụ ribbed ígwè mmanya, nkọwa mkpanaka waya bụ φ8mm ~ φ10mm, na usoro nkà na ụzụ na-agụnye ikpo ọkụ - billeting - rough rolling - medium rolling - cooling - pre-finishing - cooling - finishing - cooling - spinning. - ikuku oyi na-atụ tebụl - ikpokọta eriri igwe - ngwa ngwa jụrụ oyi, nke e ji mara ya: pasentị ihe mejupụtara kemịkalụ nke ígwè bụ c = 0.20% ~ 0.25%, si = 0.40% ~ 0.50%, mn = 1.40% ~ 1.60%, p≤ 0.045%, s≤0.045%, v = 0.015% ~ 0.020%, ndị ọzọ bụ fe na ihe na-adịghị ọcha na-enweghị atụ;Isi usoro usoro na-agụnye: okpomọkụ tapping bụ 1070 ~ 1130 Celsius C, tupu emecha okpomọkụ bụ 970 ~ 1000 Celsius C, na finishing rolling na-rụrụ.The okpomọkụ bụ 840 ~ 880 ℃;na spinning okpomọkụ bụ 845 ~ 875 ℃;okpomọkụ ikpeazụ na-atụgharị dị n'okpuru okpomọkụ recrystallization nke mpaghara austenite;a na-eme ka ọ dị jụụ ngwa ngwa site na onye na-akwado ya na tebụl igwe na-ekpo ọkụ na-ekpo ọkụ, na ụda ikuku bụ 100%;A na-ekpuchi tebụl roller site na-emechi mkpuchi mkpuchi, okpomọkụ nke ịbanye mkpuchi mkpuchi bụ 640 ~ 660 ℃, na okpomọkụ nke ịpụpụ mkpuchi mkpuchi bụ 600 ~ 620 ℃, na oge na mkpuchi mkpuchi bụ 45 ~ 55s.

Nchịkọta nka nka

The mmepụta usoro nke na-ekpo ọkụ-akpọrepu ígwè ribbed ígwè mmanya, mmiri ígwè na-ekpo ọkụ akpọrepu waya mkpanaka nkọwa bụ Φ8mm ~ 10mm, kemịkalụ uka pasent ọdịnaya nke ígwè bụ C = 0.20% ~ 0.25%, Si = 0.40% ~ 0.50% , Mn = 1.40% ~ 1.60%, P≤0.045%, S≤0.045%, V = 0.015% ~ 0.020%, ndị ọzọ bụ Fe na-apụghị izere ezere adịghị ọcha ọcha;Rolling usoro bụ: ọkụ okpomọkụ bụ 1070 ~ 1130 ℃, na tupu emecha a rụrụ.The mpịakọta okpomọkụ bụ 970 ~ 1000 ℃, na finishing Rolling okpomọkụ bụ 840 ~ 880 ℃;na spinning okpomọkụ bụ 845 ~ 875 ℃;okpomọkụ ikpeazụ na-atụgharị dị n'okpuru okpomọkụ recrystallization nke mpaghara austenite;%;Mgbe mmechi mkpuchi mkpuchi nke ihe mkpuchi ahụ, okpomọkụ nke ịbanye mkpuchi mkpuchi bụ 640 ~ 660 ℃, na okpomọkụ nke na-apụ na mkpuchi mkpuchi bụ 600 ~ 620 ℃, na oge na mkpuchi mkpuchi bụ 45 ~ 55s.Site n'ịgbakwụnye obere ihe nke V alloy na imecha na-agbagharị na obere okpomọkụ, ihe a na-emepụta ọ bụghị nanị na-eme ka ọrụ ahụ kwụsie ike, ma na-ebelata ọdịnaya alloy na ọnụ ahịa ya.

Oge nzipu: Ọgọst-30-2022