Usoro mmepụta na usoro nke akwa akwa akwa

Usoro ndabere:

Na ahịa ndị bi na Rebar ugbu a, akụkọ HRB400E maka ihe ndị ọzọ. Thezọ microalloy na-ewusi ike bụ isi ụzọ iji mepụta hrb400e n'ụwa. Microally bụ tufuo Velodium ma ọ bụ Niubium alloy, nke na-eri ọtụtụ akụ na ụba kwa afọ. N'ihi oke nke nwere ikike ịnweta Vanadium na Niobium, ntinye nke ihe ndị a na-ahụ maka ịba ọcha siri ike. Ya mere, ọ bụrụ na enwere ike belata ihe niile nke lyB40000 steel, ọ ga-amịpụta nnukwu akụ na ụba na mmekọrịta ọhaneze.

Na teknụzụ dị adị, ahịrị waya nke abụọ na-enweghị mbelata ma na-ebelata ma na-ebelata ma na-ebelata ma na-ebelata ma na-ebelata ma na-ebelata igwe na-enweghị isi, na ọdịnaya ọdịnaya nke Vanadium bụ 0.035% na 0.045%.

Patent patent CN104357741 na-ekpughe ụdị HRB400E elu-ike ala ọma jijiji na-eguzogide ala ọma jijiji na ígwè ya. Site na usoro ahụ, a na-emepụta ngwaahịa ahụ emechara site na ibelata ma na-ebelata igwe mpịakọta, nke nwere ike ịgba mbọ hụ na a na-ekwupụta ya na obere okpomọkụ, usoro a adịghị mma maka usoro mmepụta na-enweghị belata sọks. Patent patent CN1101845 na-ekpughe ụzọ nkwadebe nke elu waya φ6mm ~ hrb4se cold. Site n'enyemaka nke ike na-agba ọsọ nke akụrụngwa, obere okpomọkụ na-amalite site na ikpo ọkụ, yana nrụpụta na-enweghị microloying na-akọwa. Ihe ọghọm nke usoro a bụ na ihe achọrọ maka ike na arụmọrụ moto nke akụrụngwa siri ike nke ngwa ọrụ, nke na-ebelata ogo mmezi nke akụrụngwa na usoro a na-emepụta site na usoro a. Izu oke, o siri ike inye m obi uto.

Ntụgharị aka na teknụzụ:

Ihe okike dị ugbu a iji nye usoro maka ịmepụta ihe mgbochi na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-eme ka ọ dị elu na-ebelata ụgwọ.

Nkịtị teknụzụ nke ihe omumu:

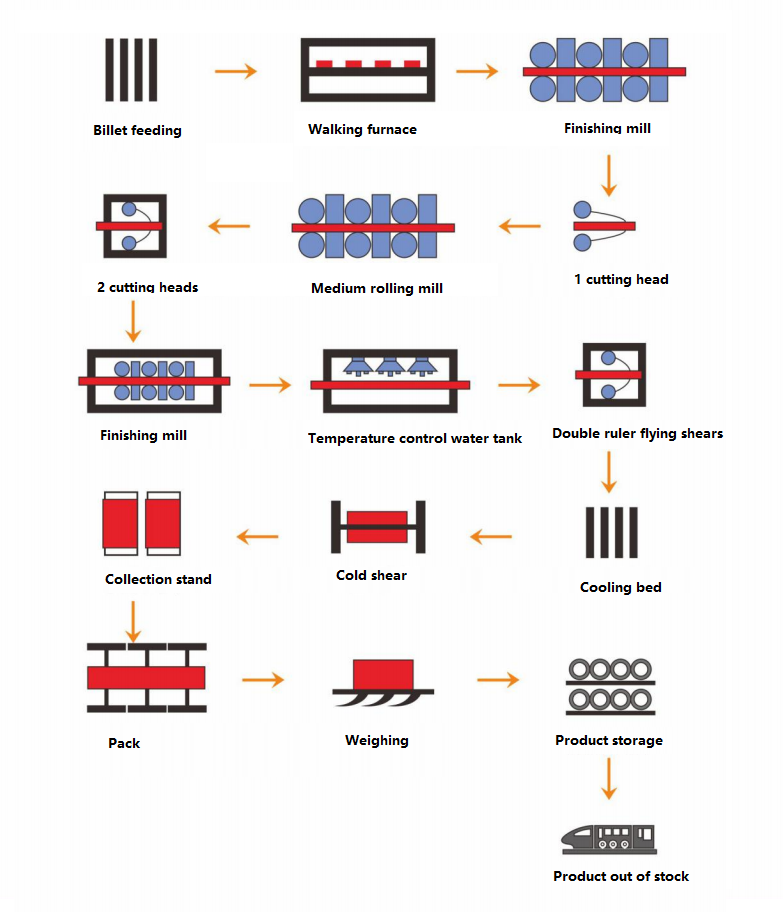

The production method of hot-rolled ribbed steel bar, the specification of ribbed steel wire rod is φ8~φ10mm, and the technological process includes heating – billeting – rough rolling – medium rolling – cooling – pre-finishing – cooling – finishing – cooling – spinning – Air-cooled roller table—coil collection—slow cooling; Ihe mejupụtara kemịkal nke steel dị na ya bụ c = 0.20% ~ 0.04%, mn 0.045%, mn 0.045%, p525%, p525%, ndị ọzọ bụ fey na-adịghị ọcha; Usoro dị mkpa na-agụnye: Okpomoku dị na ya bụ 1070 ~ 1130 ~ 1000 ~ 1000 ~ 1000 ~ 840 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~ 1000 ~. 880 ℃; ịta okpomọkụ 845 ~ 875 ℃; Ikpeazụ na-efe efe dị n'okpuru ọnụnọ nke mpaghara Austinalite; ngwa ngwa nke onye ofufe dị na tebụl jụrụ oyi, olu ikuku bụ 100%; Ọnọdụ okpomọkụ nke mkpuchi bụ 640 ~ 660 ~ 660 ℃, ọnọdụ okpomọkụ nke mkpuchi nchekwa ọkụ bụ 600 ~ 620 ℃, na oge nchekwa nchekwa ọkụ bụ 45 ~ 55s.

Principlekpụrụ nke ihe ahụ: na ọnọdụ okpomọkụ nke 840-880 ℃, a na-esikwa ike na-efe efe site na mkpọmkpọ ebe adịghị eme. Agbanyeghị, a na-emepụta ihe ndị na-emebi emebi, na nsọtụ nke ndị na-emebi emebi, yanakwa ndị na-emebi nri dị ka ala nwere akụ na-akpụ akpụ iji kewaa mkpụrụ osisi ndị Aulanite. N'oge mgbanwe sitere na Austinate na Ferrite, ma mpaghara ọka kpụ ọkụ n'ọnụ nke na-apụta ìhè na mpaghara na-emebi emebi maka ferrite, na-ebute ndozi nke ferrite mgbe agbanwechara. Obere okpomọkụ na-eme ka ọ dị obere na-eme ka ikuku na-eme mkpọtụ na etiti mịrị amị na etiti igwe na-emecha ma na-abawanye ndụ ọrụ ọrụ.

Mmetụta bara uru nke ihe omumu a: Site na itinye obere v maka microall na-ewusi ike, nke a na-emeziwanye n'oge oyi mgbe ịghasịrị, ma na-arụ ọrụ nke ọdịda na-ewusi ike. Rod waya nke na-ekpo ọkụ nwere ike nke 600-70000MPA, ike na-awụ mkpụrụ nke 420-500-500MPA, nkezi mkpụrụ aka, na AgT, nke na-ejide oke. Ike a ga-akwụ ụgwọ, yana ọnụego asambodo dị elu karịa 99%. Na-edozi nsogbu nke igwe na-eme ihe na-eme ihe dị ala, na-ebelata ọnụ ahịa nke na-edozi ahụ, ma na-eweta uru akụ na ụba.

Ụzọ zuru ezu

A na-akọwawanye ọdịnaya nke ihe dị ugbu a n'okpuru na njikọta na ntinye aka.

Usoro nrụpụta nke otu dị elu waya φ8mm ~ φ10mmhrb400e coiled eju ejula. The rolling process is: outgoing temperature: 1080~1120℃, entering pre-finishing rolling 1030~1060℃, entering finishing rolling temperature: 850~870℃, spinning temperature: 850~870℃, fan air volume 100%, entering insulation cover temperature 640~660℃, 600~620℃ out of the heat preservation cover, the time in the heat Ebe mkpuchi mkpuchi dị 45 ~ 55s, ọ na-ajụkwa oyi. Ihe mejupụtara kemịkalụ nke waya mkpanaka nke ihe eji emepụta dị ugbu a gosipụtara nke dị ugbu a na tebụl 1, Njirimara nke waya mkpanaka nke ihe e mepụtara ugbu a na tebụl 2.

Ihe mejupụtara kemịkalụ (wt%) nke waya mkpanaka nke okpokoro

Tebụl 2 usoro ihe eji eme ihe atụ

Ike mkpụrụ nke elu waya φ8mm ~ φ10mmhrb400e coeed ejula site na usoro ihe dị na 420, ike na-eme ka ọ dị elu karịa 1.35, na usoro metalpograic bụ turrite na pearlite. , arụmọrụ zuru oke, ike zuru oke na mpaghara agt, ihe ịga nke ọma nke usoro a dị mkpa iji belata ọnụahịa na-abawanye na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe eji emepụta ihe.

Atụmatụ teknụzụ:

1 c = 0.20% ~ 0.25%, si = 0.40%, mn = 1.045%, p545%, p525%, ihe ndị ọzọ bụ ụgwọ adịghị ọcha; Usoro dị mkpa na-agụnye: Ọnọdụ okpomọkụ bụ 1070 ~ 1130 ~ 1130 ~ 1070 ~ 1000 ~ 1000 Celsius C, na a na-eme ka a na-eme obere. Ọnọdụ okpomọkụ bụ 840 ~ 880 ℃; Internening okpomoku bu 845 ~ 875 ℃; Ikpeazụ na-efe efe dị n'okpuru ọnụnọ nke mpaghara Austite; Ọ na-ajụ ngwa ngwa site n'aka onye ofufe na tebụl jụrụ ikuku, na olu ikuku dị 100%; A na-ekpuchi okpokoro ahụ site na imechi mkpuchi mkpuchi, ọnọdụ okpomọkụ nke ịbanye mkpuchi mkpuchi bụ 640 ~ 660 ℃, na oge mkpuchi mkpuchi bụ 45 ~ 55s.

Nchịkọta nka

Nkọwapụta nke na-emepụta ihe nke na-acha uhie uhie na-acha uhie uhie na-acha uhie uhie na-acha uhie uhie na-ekpo ọkụ bụ φ8mm ~ 0.20%, mn 0.04%, p50%, s545.045%, V = 0.015% ~ 0.020%, ndị ọzọ bụ ụgwọ na ihe adịghị ọcha; Usoro ntupu ahụ bụ: Okpomoku a bu 1070 ~ 1130 ℃, na emechaala. Okpomoku nke na-ebugharị bụ 970 ~ 1000 ℃, na-eme ka ọnọdụ dị iche iche bụ 840 ~ 880 ℃; Internening okpomoku bu 845 ~ 875 ℃; Ikpeazụ na-efe efe dị n'okpuru ọnụnọ nke mpaghara Austite; %; Mgbe emechara mkpuchi mkpuchi nke roller, ọnọdụ okpomọkụ nke ịbanye mkpuchi mkpuchi bụ 640 ~ 660 ℃, na oge okpomọkụ nke mkpuchi bụ 45 ~ 55s. Site na ịgbakwunye obere ego V alloy na imecha nke ukwuu na ọnọdụ okpomọkụ, ọ bụghị naanị na-eme ka ọrụ kwụsie ike, kamakwa na-ebelata ọdịnaya alloy na ọnụ ahịa.

Oge Post: August-30-2022